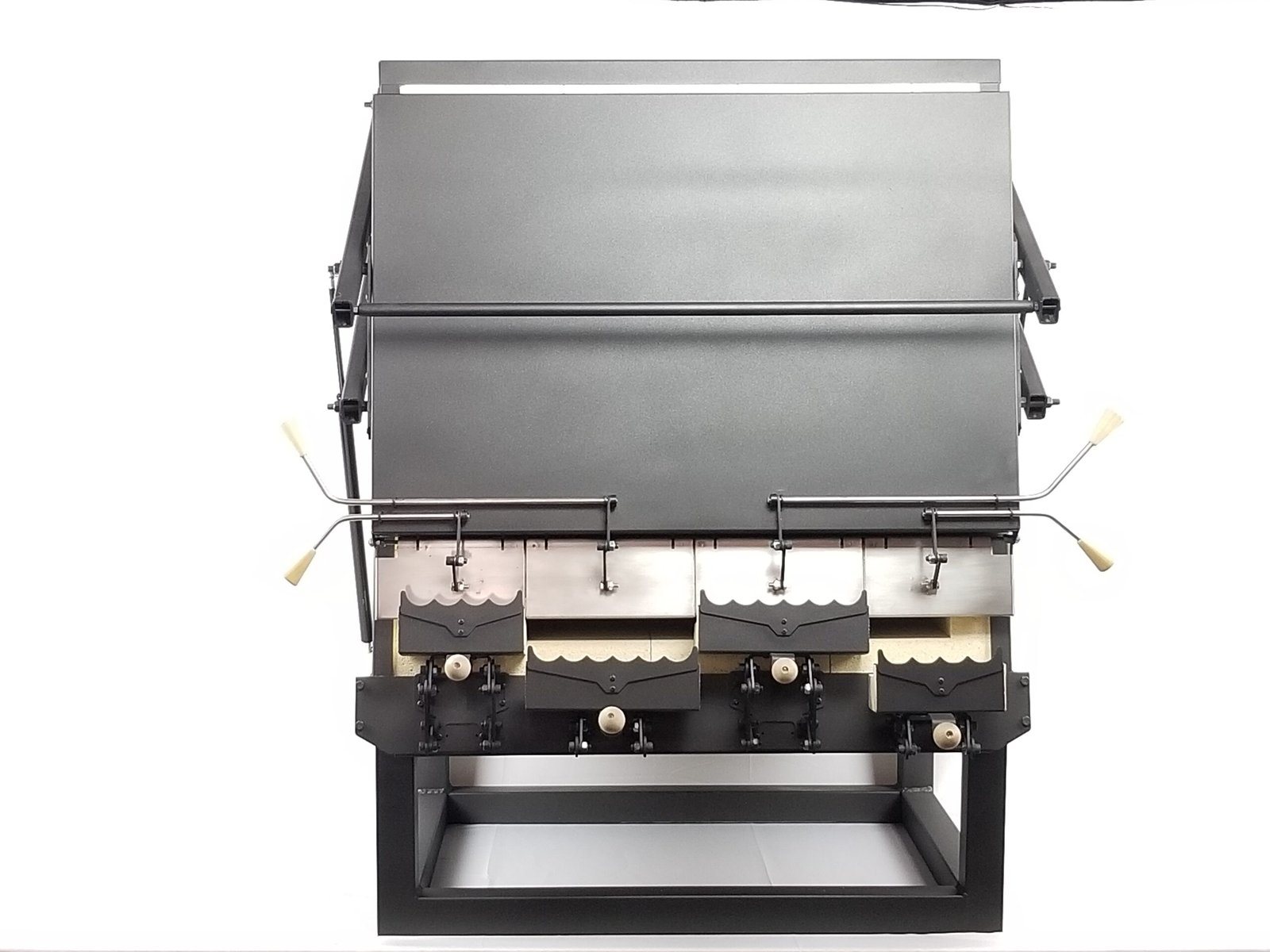

The C-26, also known as the Mendocino model, is the largest in our Professional Series lamp working kilns line. One of two of the most technical kilns in the industry, with plenty of room for your lampworking needs. This model is very similar in size to our Hops model, but adds 26 inches of height for artists that requite the space for taller vessels while still being able to handle their garaging needs with nine doors available, as well as our highly technical door style, Lazy Boy hinges, and high temperature powder coat. This kiln is extremely well insulated resulting in inexpensive daily operating cost with a simplified electrical system, making it a great overall value and leader in it’s size category. Made for serious artists that need the highest quality equipment to match their intensity.

The C-26 was designed for large scale solid and hollow vessel, multi sectional, collaboration, and a variety of other high end lamp working needs. This model has a recommended maximum temperature of 1400F and carries our standard 2 year electrical and lifetime craftsmanship warranty.

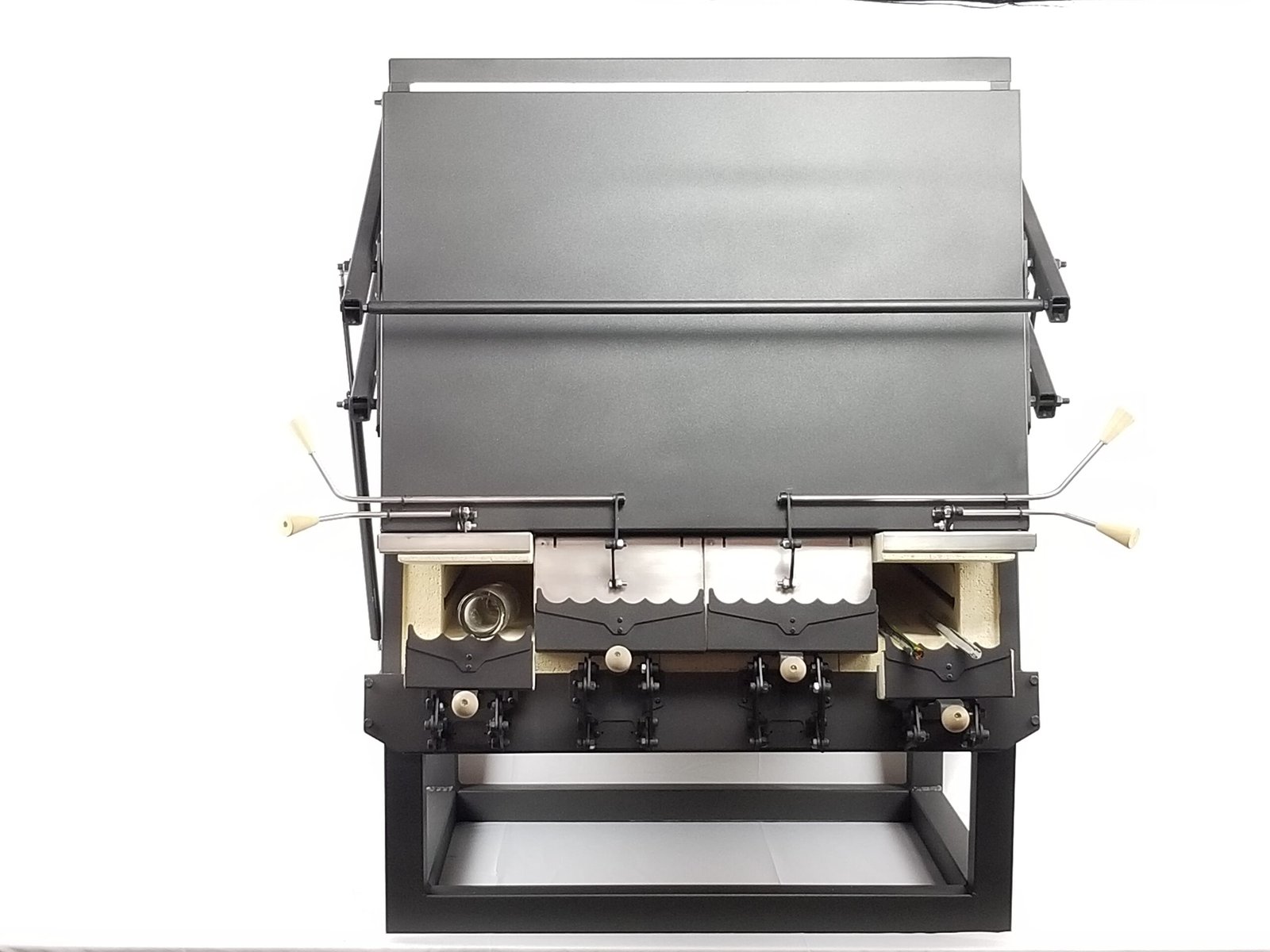

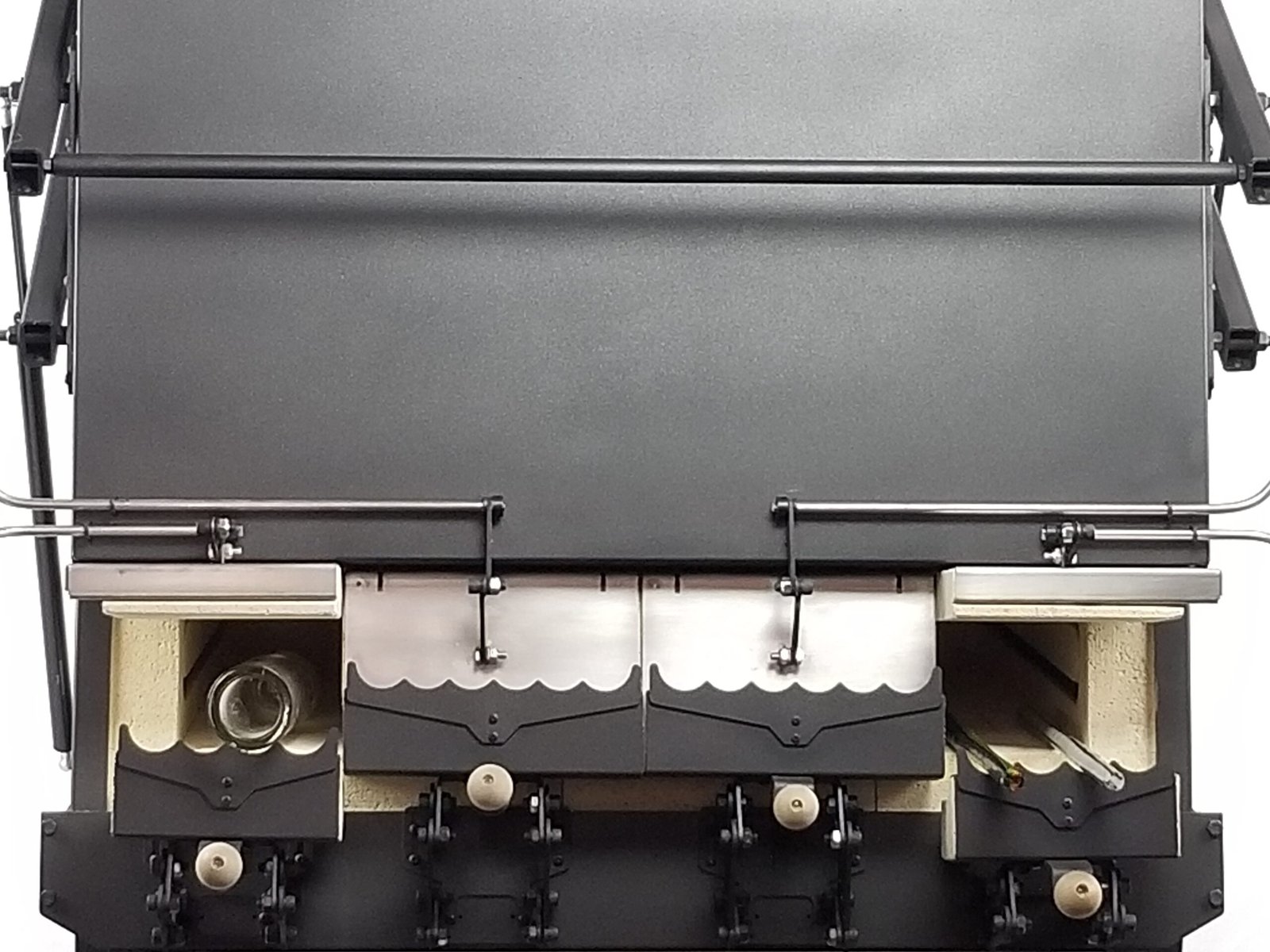

- All new main door design incorporating five individual fully adjustable doors that offer a variety of versatility and options to make accessibility simple and highly functional.

- 10 degree angle in the main chamber face that helps produce even heat throughout the interior chamber. This angled chamber cut also provides even wear and a tight door seal on every unit.

- This model comes standard with our next level Lazy Boy hinges allowing them to pivot from multiple points for smooth action.

- Built in scalloped rod rests attached on both flip down point rests that keep handles and punties securely in place and pieces level with the kiln floor.

- 304 stainless steel used in the bead doors to handle temperature in high heat areas.

- Fully adjustable pressure assisted door design allowing all doors to firmly stay open or in any position. *patent pending*

- Our Profession Series kilns do NOT use any fiber board insulation in the lids, main doors, or bead doors as fiber board is an inadequate source of insulation and a major source of heat leakage and shrinkage when used as a sole insulator in annealing kilns.

- Door gapping has been minimized to provide maximum efficiency, without sacrificing function.

- Perfectly balanced main door and counterweight with new compact counterweight design allowing this model to fit into tighter spaces in a studio or workshop. Full adjustability to offer the perfect tension when opening/ closing main door.

- Precise heating element placement in the chamber in combination with the 10 degree chamber angle help focus heat near the lower front portion of the floor to focus the heat where you need it and keep your work stable while accessing lower doors.

- Extremely quick heat up time in this model, taking approximately 20-25 minutes to reach 1000F+ in most cases.

- Well placed thermocouple providing extremely accurate temperature throughout the chamber.

- Simple and precise electrical system making troubleshooting and offsite repairs much more simplified for customers.

- Meticulous and unrivaled brick and mortar work in each and every lamp working kiln.

- Detailed quality control process and 3-point inspection before product leaves our factory.

- Each metal component or piece of hardware such as handles, hinges, arms, etc. is all custom designed and manufactured in house by Aim Manufacturing. No low quality off the shelf hardware parts used on our product which is one of the biggest differences that separates us from other manufacturers.

- New slotting design in the lower frame and wire pan areas to allow for more airflow to keep electronic components much cooler to extend their lifespan.

- This model is prefabricated and set up for accessories such as rod rests, upgraded relays, modified hinges, and other modifications than can be added at time of purchase or easily added later.

- High temperature primer, metallic stove paints, and high quality powder coatings used exclusively.

- Wood or high temperature anabolic handles used to keep exterior handles cool to the touch while giving the kiln a pleasing aesthetic exterior appearance.

- We offer a wide range of programmable digital controllers that were actually designed for lamp working to meet your individual needs.